FUJI NXT nozzles support

SMT Replacement nozzles for Fuji NXT machines include models for different heads like H01, H04, H08/H12, V12, and H24.

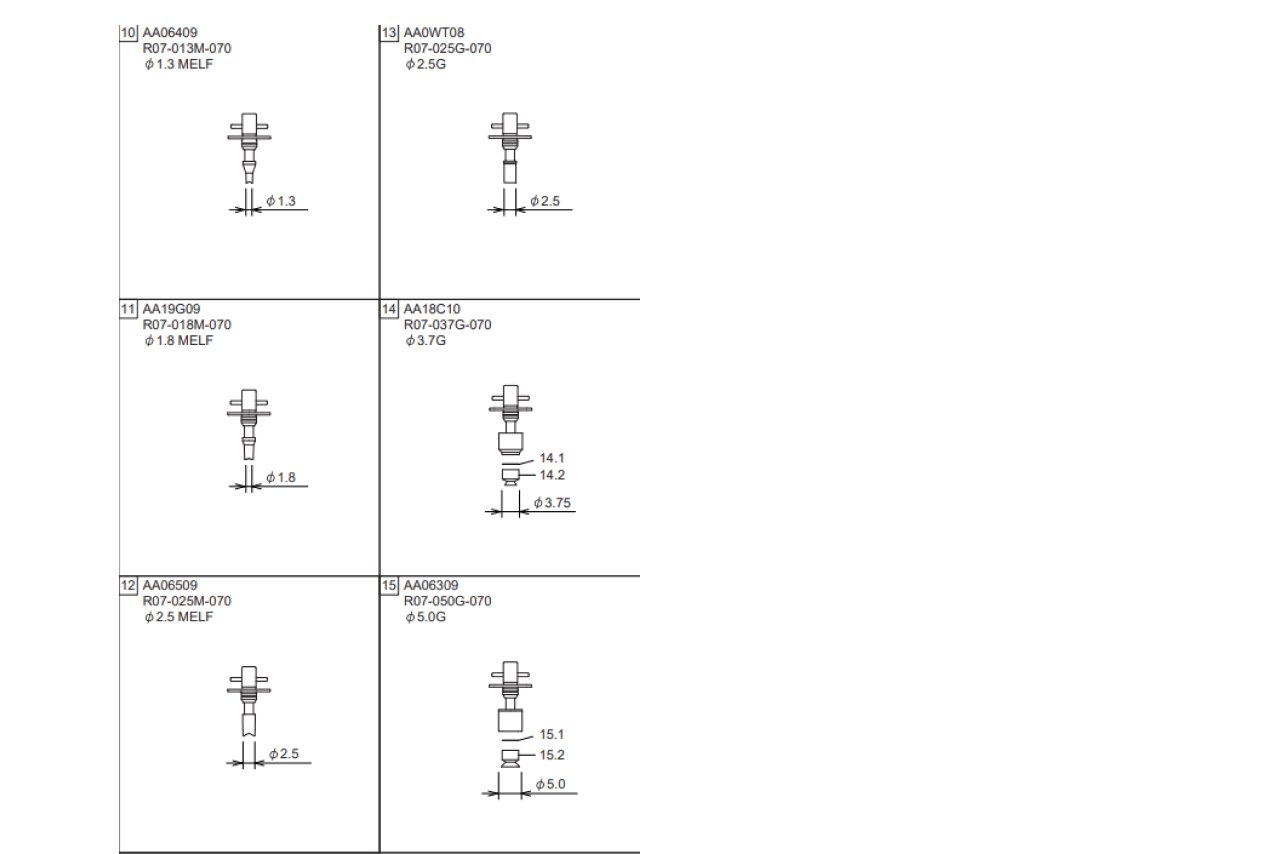

Common types are 0.3mm, 0.35mm, 1.8M, 2.5M, 3.7G, and 5.0G, supporting various component sizes and applications

Fuji NXT nozzles chart key features

The Fuji NXT nozzles chart is a vital resource for manufacturers involved in Surface Mount Technology (SMT), offering a comprehensive overview of the various nozzles compatible with Fuji NXT placement heads. One of the key features of this chart is its detailed specifications for each nozzle type, including dimensions, part compatibility, and placement accuracy. This allows users to quickly identify the appropriate nozzle for their specific component requirements, ensuring optimal performance during PCB assembly. By providing essential information at a glance, the chart enhances operational efficiency and minimizes downtime associated with incorrect nozzle selection.

Another significant aspect of the Fuji nozzle specification is the inclusion of unique identification codes for each nozzle. Every Fuji NXT nozzle features both an original data matrix code and an OEM color matrix code, facilitating easy identification by both operators and machine software. This feature is particularly beneficial in high-volume production environments where quick changes between different nozzles are necessary. The ability to swiftly identify and switch nozzles reduces the risk of errors and enhances overall productivity, making it easier to maintain high standards of quality in electronic manufacturing.

The versatility of Fuji nozzles is also evident in their design, which accommodates a wide range of component types and sizes. For example, the SMT Fuji nozzle can handle everything from small chip components to larger odd-form parts. This adaptability is crucial in today’s fast-paced electronics market, where manufacturers often deal with varying production volumes and component specifications. The availability of specialized nozzles, such as the Fuji NXT chip nozzle, further illustrates this flexibility, allowing for high-speed placement of small chips while ensuring precision and accuracy.

In conclusion, the SMT NXT nozzle chart serves as an indispensable tool for manufacturers seeking to optimize their SMT processes. By providing detailed specifications, unique identification codes, and showcasing the versatility of various nozzles, it empowers users to make informed decisions that enhance productivity and quality in PCB assembly. As technology continues to evolve, having access to such comprehensive resources will be critical for staying competitive in the ever-changing landscape of electronic manufacturing.

FUJI NXT nozzles for different placing heads: H12S, H08, H04, V12,H24,H0F,H04SF and H01 heads

The Fuji NXT series features several placement heads, each designed for specific applications and component sizes. Here are the key differences among the H12S, H08, H04, V12, H24, H0F, H04SF, and H01 heads:

Head Type | Nozzle Quantity | Max Part Size | Max Part Height | Placing Accuracy (3σ) | Throughput (CPH) |

H12S | 12 | 5 x 5 mm | 3 mm | ±0.050 mm | 22,500 |

H08 | 8 | 7.5 x 7.5 mm | 6.5 mm | ±0.050 mm | 10,500 |

H04 | 4 | 38 x 38 mm | 9.5 mm | ±0.066 mm | 6,500 |

V12 | 12 | 7.5 x 7.5 mm | 6.5 mm | ±0.040 mm | 25,000 |

H24 | 12 | Up to 74 x 74 mm | Up to 25.4 mm | ±0.025 mm | Up to 42,000 |

H0F | 1 | Up to 74 x 74 mm | Up to 25.4 mm | ±0.030 mm | 4,700 |

H04SF | 4 | Up to 18 x 18 mm | Up to 9.5 mm | ±0.040 mm | Not specified |

H01 | 1 | Up to 74 x 74 mm | Up to 25.4 mm | ±0.066 mm | 4,200 |

Key Differences Explained

- Nozzle Quantity: One of the most significant differences is the number of nozzles each head can accommodate. The H12S and V12 heads feature the highest capacity with twelve nozzles, making them ideal for high-speed assembly lines that require rapid placement of small components. In contrast, the H01 and H0F heads are designed for larger components and have only one nozzle.

- Max Part Size and Height: Each head is designed for different maximum part sizes and heights. For example, the H24 head can handle larger parts up to 74 x 74 mm, while the H04SF is limited to smaller parts up to 18 x 18 mm. This variation allows manufacturers to select a head based on their specific component requirements.

- Placing Accuracy: The placing accuracy varies among the heads, with the H24 achieving an impressive accuracy of ±0.025 mm (3σ), making it suitable for high-precision applications involving small components. The other heads, such as the H08 and V12, maintain a similar accuracy of ±0.040 to ±0.050 mm, while the H01 has a slightly lower precision of ±0.066 mm.

- Throughput Rates: Throughput rates also differ significantly across these heads. The H24 head can achieve up to an impressive throughput of up to 42,000 components per hour in productivity priority mode, while the H12S reaches up to 22,500 cph for smaller parts. The lower throughput rates of the H01 and H0F heads reflect their design for larger components rather than speed.

In summary, understanding these key differences among the Fuji NXT heads allows manufacturers to choose the right placement head that aligns with their production goals, whether they prioritize speed, accuracy, or compatibility with specific component sizes in their SMT processes.

FUJI NXT Nozzles List for Placement Heads

Head Type | Nozzle Model | Part Number | Nozzle Size (Diameter) | Special Features |

H01 | Standard | R36-150-260 | 1.0 mm – 20.0 mm | Compliant and MELF components |

Large Component | AA8LX09 | 2.5 mm | For larger components | |

Large Component | AA06300 | 5.0G mm | High-speed placement | |

H02 | Standard | AGPH-9560 | 0.7 mm | General-purpose nozzle |

Standard | AGPH-9410 | 1.0 mm | Disk-type nozzle | |

MELF | AGPH-9050 | 1.3 mm | MELF component compatibility | |

H04 | Standard | AA06W00 | 1.0 mm | Ceramic tip |

Standard | AA06X00 | 1.3 mm | General-purpose nozzle | |

MELF | AA22Z14 | 1.8 mm | MELF-specific nozzle | |

Large Component | AA07B00 | 5.0 mm | Medium purple | |

Large Component | AA07C00 | 7.0 mm | For large components | |

H08/H12 | Standard | AA05600 | 0.45/0.3 mm | Yellow nozzle |

Standard | AA05700 | 0.7/0.5 mm | Blue nozzle | |

General Purpose | AA05800 | 1.0 mm | Pink nozzle | |

MELF | AA06400 | 1.3M mm | Orange MELF nozzle | |

Large Component | AA20D00 | 3.7 mm | Yellow-green | |

Large Component | AA20E00 | 5.0 mm | Medium purple | |

V12 | High Precision | R07-004-070 | 0.4 mm | Ceramic tip for high precision |

General Purpose | R07-010-070 | Up to 5.0 mm | Versatile component handling | |

H24 | High Precision | R047-002-035 | Up to 74 x 74 mm | Handles large components |

Key Notes:

- H01 and H02 Heads: These are designed for larger components, with nozzles ranging from standard sizes (e.g., 1.0 mm) to specialized nozzles for larger parts (e.g., up to 20 mm).

- H04 Head: Suitable for both small and medium-sized components, with options for MELF and larger parts.

- H08/H12 Heads: These are high-speed heads with nozzles ranging from ultra-small sizes (e.g., 0.45/0.3 mm) to larger sizes (e.g., up to 5.0G).

- V12 Head: Optimized for high precision with ceramic tips, ideal for small and delicate components.

- H24 Head: Designed for large parts with a focus on precision placement.

10 Reasons buy FUJI NXT nozzles

- High-Quality Products

We offer premium SMT machine spare parts that are rigorously tested to ensure durability, reliability, and precise performance in demanding production environments.

- Comprehensive Product Range

From SMT nozzles and feeders to essential spare parts, we provide a one-stop shop for all your SMT machine requirements, compatible with leading brands like Yamaha, Panasonic, Fuji, and Juki.

- Industry Expertise

With years of experience in the SMT industry, we understand the unique challenges of electronics manufacturing and are equipped to provide tailored solutions to meet your production goals.

- Competitive Pricing

We combine quality and affordability, offering industry-leading spare parts at competitive prices, ensuring the best value for your investment.

- Fast and Reliable Shipping

We know downtime is costly. That’s why we maintain efficient logistics and ensure fast, dependable shipping, minimizing disruptions to your production line.

- Customization Options

Our expertise allows us to provide customized parts or specialized solutions for unique or challenging production needs, ensuring compatibility with your equipment and processes.

- Global Customer Support

Our dedicated support team is always ready to assist you, offering expert guidance and prompt service to address your concerns, no matter where you are in the world.

- Trusted by Industry Leaders

Our high standards and customer-first approach have earned us the trust of clients in diverse markets, making us a reliable partner for your SMT spare parts needs.

- Commitment to Innovation

We stay ahead of industry trends by continually updating our products and solutions, ensuring you benefit from the latest advancements in SMT technology.

- Long-Term Partnerships

We prioritize building lasting relationships with our clients by consistently delivering high-quality products, exceptional service, and ongoing support to help you achieve long-term success.

Buy FUJI NXT nozzles for your NXT pick and place machine

Precision Crafted, Performance Delivered

Workflow process for ordering FUJI NXT Nozzles for your SMT machines

- Customer Inquiry

Customers contact us with their requirements, detailing the spare parts they need, such as SMT nozzles, feeders, or machine components. This can be done via email, phone, or our online platform.

- Product Consultation

Our team analyzes the customer’s needs, machine models, and production requirements. We provide expert advice to ensure the selection of the right parts for optimal compatibility and performance.

- Quotation and Confirmation

We provide a detailed quotation, including product specifications, pricing, and lead times. Once the customer approves the quotation, the order is confirmed.

- Inventory Check or Customization

If the required spare parts are in stock, we prepare them for shipment. For non-standard or customized parts, the manufacturing process begins to ensure precise specifications.

- Quality Control

All spare parts undergo thorough quality inspections, including dimensional checks, material testing, and performance verification, ensuring they meet our high standards.

- Packaging and Labeling

The parts are carefully packaged to prevent damage during transit. Each package is labeled with detailed product information, including part numbers, descriptions, and compatibility.

- Shipping and Delivery

Orders are shipped using reliable logistics partners, ensuring fast and secure delivery. Tracking information is provided to the customer for real-time updates.

- Installation Support

We provide guidance or technical assistance to ensure the proper installation of spare parts, minimizing downtime and optimizing machine performance.

- After-Sales Support

Our support team follows up with customers to address any issues, provide additional information, or assist with future requirements. We are committed to ensuring customer satisfaction.

- Continuous Improvement

We encourage feedback to improve our processes, products, and services. This helps us meet evolving customer needs and maintain industry-leading standards