What are SMT nozzles?

SMT nozzles are small tools used in SMT (Surface Mount Technology) machines to pick up and place electronic parts on circuit boards. They work by using suction—like a tiny vacuum—to lift parts such as resistors, capacitors, and chips from a tray or tape, then place them exactly where they need to go on the board.

Each nozzle has a specific shape and size, depending on the part it needs to handle. For example, small round nozzles are used for tiny components, while larger or custom-shaped nozzles are used for bigger or special parts. They are made from strong materials like metal, ceramic, or carbon fiber to last longer and work accurately.

Different SMT machines (like those from Fuji, Juki, Yamaha, or Panasonic) use different types of nozzles. Using the right SMT nozzles helps the machines work faster and more accurately, which saves time and avoids mistakes.

Over time, nozzles can get dirty or worn out, so they need to be cleaned or replaced to keep the machine running well. In short, SMT nozzles are key parts that help build electronics quickly and precisely in factories.

。

Table of Contents

Fuji Nozzles

Panasonic Nozzles

JUKI Nozzles

Ersa Solder Nozzles

Siements Nozzles

Dispenser Nozzles

The role of SMT nozzles and their importance in mounters

SMT nozzles are key to placement accuracy because they directly pick and place components onto the PCB. The right nozzle size and shape ensures stable suction and precise alignment. If the nozzle is worn or mismatched, it can cause errors, dropped parts, or slow production. High-quality, well-maintained nozzles help machines run faster and more accurately, reducing defects and improving efficiency. Since nozzles are the main contact point between the machine and the component, their performance directly affects overall SMT production quality.

Types of SMT Nozzles

There are many types of SMT nozzles, and choosing the right one depends on your machine and components. Nozzles can be grouped by brand, such as Fuji, Juki, Yamaha, Panasonic, and Samsung, each with their own compatible models and specifications. Each brand offers various nozzle sizes to match different parts, from small chips to larger ICs. Common models like Fuji H01, Juki 503, or Yamaha 311A are widely used in the industry. In addition to standard nozzles, many factories also use custom nozzles to handle special-shaped or delicate components. Custom nozzles are designed for specific needs, while standard nozzles are more versatile and easier to replace. Understanding these types helps improve pick-and-place accuracy and reduce machine downtime.

Exploring FUJI NXT Nozzles: Key Models for Precise Component Placement

FUJI NXT nozzles are used in FUJI’s NXT series pick-and-place machines for high-speed, precise component placement. Each nozzle type fits a specific placement head and component range. For example:

H01 nozzle: For 0201 to 0603 chips, fast and accurate, mainly for small passive components.

H04 nozzle: Handles 0402 to 1206 chips, ideal for general-purpose placement.

H08/H12 nozzles: Used for larger ICs and odd-shaped components, suitable for high-mix production.

H24 nozzle: Ultra-high-speed, supports up to 24 nozzles per head, for mass production.

These nozzles are typically made of ceramic or stainless steel, offering strong suction, wear resistance, and compatibility with auto-change systems. Choosing the right model helps reduce placement errors and improve line efficiency. FUJI nozzles are widely used in advanced electronics manufacturing like smartphones, automotive, and medical devices.

- FUJI NXT H01/H02 Nozzles: Precision Placement for Ultra-Small Components

If you’re looking for FUJI compatible SMT nozzles that deliver both speed and accuracy, the AA0HL00, AA0HM00, AA0HN00, AA08500, AA07200, and AA08000 models are top choices for the FUJI NXT H01 and H02 heads.

These high-precision pick and place nozzles are specially engineered for ultra-small component placement, including 0201 and 0402 chips. Made from durable ceramic materials, they offer excellent suction stability, quick response times, and reduced placement errors—key features for improving production yield.

As some of the best SMT nozzles for FUJI NXT, they’re ideal for high-density PCB assembly lines. Their support for automatic nozzle exchange minimizes downtime and keeps your lines running smoothly, boosting efficiency and reducing manual intervention.

Whether you’re upgrading your existing system or sourcing reliable replacements, these SMT nozzles combine performance, durability, and compatibility—making them a smart investment for any serious electronics manufacturing setup.

H01 nozzle 1.8 AA0HL00 R36-018-260

H01 nozzle 2.5 AA0HM00 R36-025-260

H01 NOZZLE 3.7 AA0HN00 R36-037-260

H01 NOZZLE 3.7G AA08500 R36-037G-260

H01 NOZZLE 5.0G AA07200 R36-050-260

H01 NOZZLE 7.0 AA08000 R36-070-260

| PART No. | NAME | Specification | Material | Remark |

|---|---|---|---|---|

| AA0AS00 | Φ1.0 | Φ1.0/Φ0.7 | CERAMIC | |

| AA06800 | Φ1.3 | Φ1.3/Φ1.0 | CERAMIC | |

| AA0HL00 | Φ1.8 | Φ1.8 | CERAMIC | |

| AA0HM00 | Φ2.5 | Φ2.5 | CERAMIC | |

| AA08410 | Φ2.5G | Φ2.5 | RUBBER | |

| AA0HN00 | Φ3.7 | Φ3.7 | CERAMIC | |

| AA08500 | Φ3.7G | Φ3.7 | RUBBER | |

| AA0HR01 | Φ5.0 | Φ5.0 | CERAMIC | |

| AA07200 | Φ5.0G | Φ5.0 | RUBBER | |

| AA08000 | Φ7.0 | Φ7.0 |

- Enhancing PCB Assembly with FUJI NXT H04/H04s place head nozzles

When it comes to high-precision SMT assembly, the FUJI NXT H04 nozzles stand out for their versatility and performance. Compatible models such as AA06Y00, AA06X00, AA06W00, AA07F00, R19-100G-155, and AA07E00 are designed to handle components ranging from 0402 to 1206 with exceptional accuracy.

Engineered for both speed and stability, these SMT nozzles offer strong, reliable suction—critical for precise placement of small and medium-sized components. Their ceramic construction not only enhances durability but also minimizes wear over time, making them a smart long-term investment.

For manufacturers focused on throughput, the H04S variants deliver high-speed handling without compromising precision. And thanks to full support for automatic nozzle exchange, both H04 and H04S models help improve overall line efficiency and reduce changeover downtime.

Whether you’re maintaining a lean SMT production line or scaling up for higher volumes, these FUJI NXT compatible nozzles bring the performance and reliability modern electronics assembly demands.

1.0 Nozzle AA06W00

1.3 Nozzle AA06X00

1.8 Nozzle AA06Y00

2.5 Nozzle AA07F00

10.0 Nozzle R19-100G-155

15 Nozzle AA07E00

| PART No. | NAME | Specification | Material | Remark |

|---|---|---|---|---|

| AA06W00 | Φ1.0 | Φ1.0/Φ0.7 | CERAMIC | |

| AA06X00 | Ø1.3 | Φ1.3/Φ1.0 | CERAMIC | |

| AA06Y00 | Ø1.8 | Φ1.8 | CERAMIC | |

| AA06Z00 | Ø2.5 | Φ2.5 | CERAMIC | |

| AA07F00 | Ø2.5G | Φ2.5 | RUBBER | |

| AA07A00 | Φ3.7 | Φ3.7 | CERAMIC | |

| AA00G00 | Ø3.7G | Φ3.7 | RUBBER | |

| AA07B00 | Ø5.0 | Φ5.0 | CERAMIC | |

| AA00H00 | Ø5.0G | Φ5.0 | RUBBER | |

| AA07C00 | Φ7.0 | Φ7.0 | METAL | |

| AA07K00 | Ø7.0G | Φ7.0 | RUBBER | |

| AA07D00 | Φ10.0 | Φ10.0 | METAL | |

| AA07L00 | Φ10.0G | Φ10.0 | RUBBER | |

| SPECIAL | CNT | DATA for ON (LED, LENS) | SPECIAL |

The FUJI NXT JIG nozzle, including part numbers AA06A00, AA0EX07, AA0ZL00, AA8XH08, AA7AK04, and AA7AH06, is a critical component for efficient SMT (Surface Mount Technology) production. It is specifically designed for use with FUJI NXT series pick-and-place machines, ensuring precise handling of components during assembly. Known for its high-quality construction, the FUJI NXT JIG nozzle ensures consistent performance, reducing downtime and enhancing production speed. By maintaining optimal alignment and placement accuracy, this nozzle helps manufacturers achieve high-quality results in their PCB assembly processes. Its durable design also contributes to longer service life, making it a reliable choice for high-volume production lines.

J06 Nozzle AA0ZL00

J17 Nozzle AA7AH06

J24 Nozzle AA8XH00

J01 Nozzles AA06A00

J02 Nozzle AA0EX07

J18 Nozzle AA7AK04

| PART No. | NAME | Specification | Material | Remark |

|---|---|---|---|---|

| Φ1.0 | Φ1.0/Φ0.7 | CERAMIC | ||

| AA8TE00 | Φ1.3 | Φ1.3/Φ1.0 | CERAMIC | |

| AA8WW00 | Φ1.8 | Φ1.8 | CERAMIC | |

| AA8WX00 | Φ2.5 | Φ2.5 | CERAMIC | |

| AA8XA00 | Φ2.5G | Φ2.5 | RUBBER | |

| AA93W00 | Φ3.7 | Φ3.7 | CERAMIC | |

| AA8XB00 | Φ3.7G | Φ3.7 | RUBBER | |

| AA93X00 | Φ5.0 | Φ5.0 | CERAMIC | |

| AA8XC00 | Φ5.0G | Φ5.0 | RUBBER | |

| AA93Y00 | Φ7.0 | Φ7.0 | METAL | |

| AA8XD00 | Φ7.0G | Φ7.0 | RUBBER | |

| Φ10.0 | Φ10.0 | METAL | ||

| Φ10.0G | Φ10.0 | RUBBER | ||

| SPECIAL | CNT | DATA for ON (LED, LENS) | SPECIAL |

- FUJI NXT H08/H12/V12 Nozzles: High-Speed Solutions for Ultra-Small Component Placement

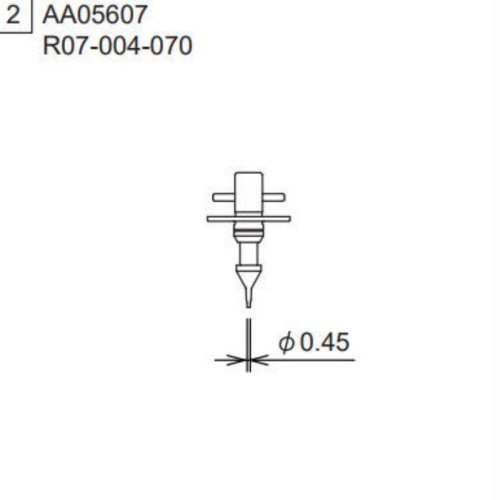

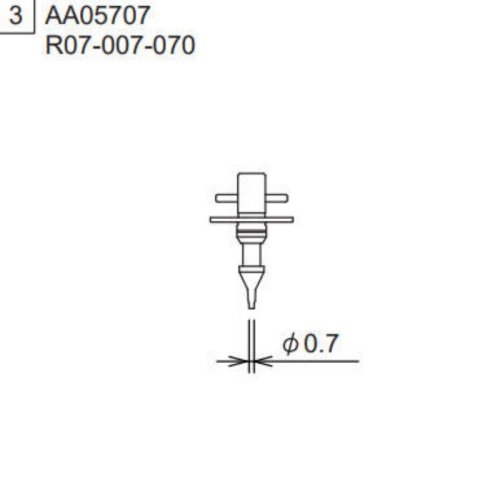

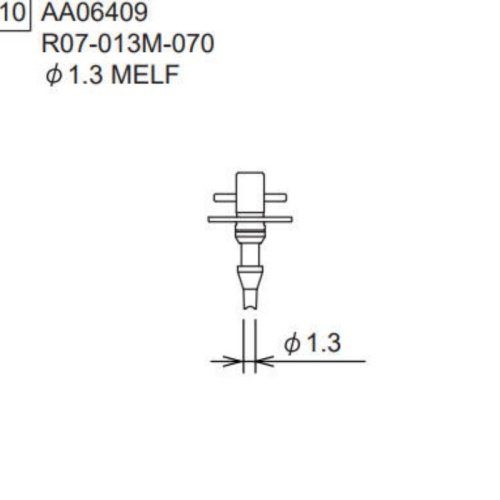

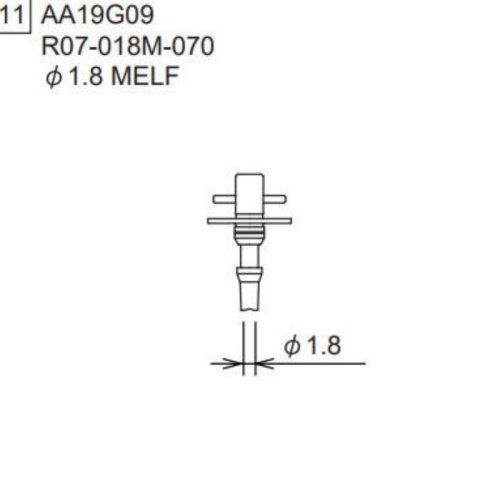

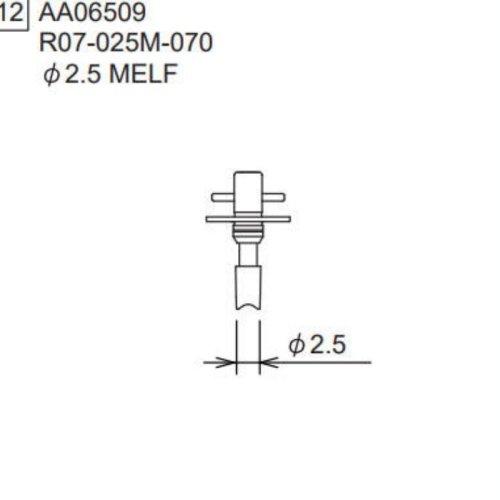

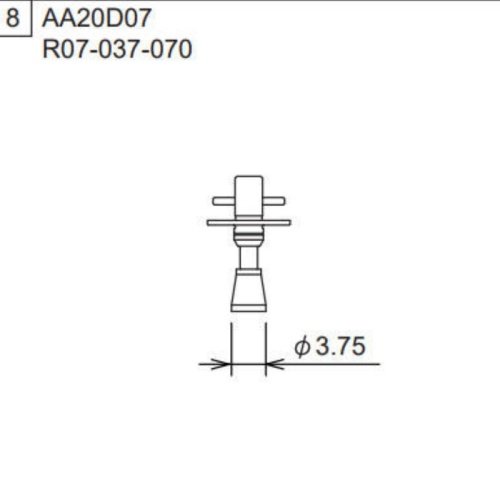

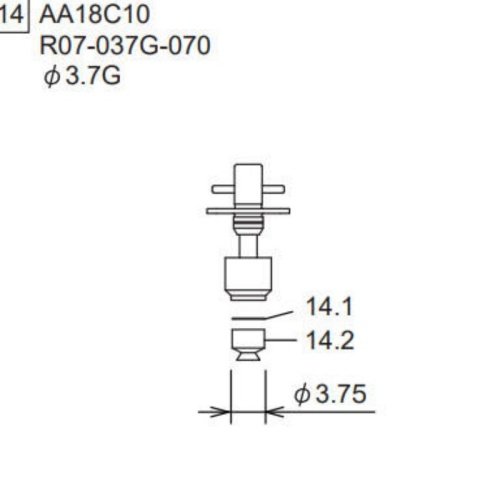

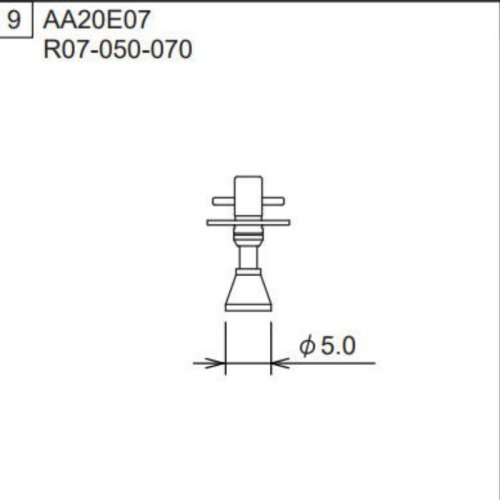

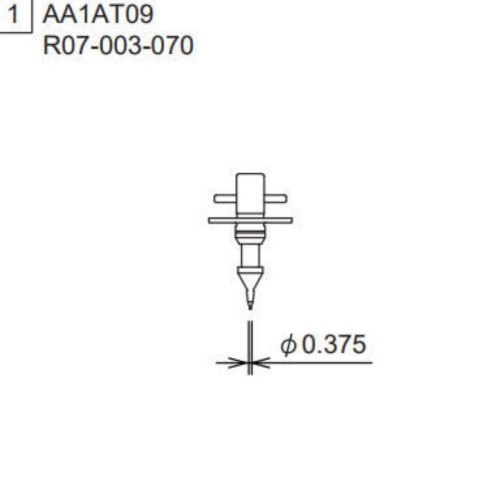

The FUJI NXT H08, H12, and V12 nozzles bring exceptional flexibility and accuracy to SMT lines, supporting components like R07-004-070, AA05607, R07-013M-070, and AA06409. Whether you’re working with small parts or larger models such as R07-018M-070, AA19G09, or R07-037G-070, AA18C, these nozzles deliver consistent, high-speed placement. Designed to work seamlessly with parts including R07-007-070, AA05707, and R07-025M-070, AA06509, they’re crafted from high-durability materials for lasting performance. For large-scale assembly involving nozzles like R07-050-070, AA20E07, or R07-003-070, AA1AT09, FUJI’s H and V series are trusted across the industry for precision and reduced downtime..

0.4 Nozzle AA05607

0.7 Nozzle AA05707

1.3M Nozzle AA06409

1.8M Nozzle AA19G09

2.5M Nozzle AA06509

3.75 Nozzle AA20D07

3.7G Nozzle AA18C10

5.0 Nozzle AA20E07

0.3 Nozzle AA1AT09

| PART No. | NAME | Specification | Material | Remark |

|---|---|---|---|---|

| AA1AT00 | Ø0.3 | Φ0.4/Φ0.25 | CERAMIC | |

| AA05600 | Ø0.4 | 0.4×0.3 | CERAMIC | |

| Φ0.5 | Φ0.55/0.35×0.25 | CERAMIC | ||

| Φ0.5C | 0.55×0.45 | CERAMIC | ||

| AA05700 | Ø0.7 | Φ0.7/Φ0.38 | CERAMIC | |

| AA05800 | Ø1.0 | Φ1.0/Φ0.7 | CERAMIC | |

| AA20A00 | Ø1.3 | Φ1.3/Φ1.0 | CERAMIC | |

| AA20B00 | Ø1.8 | Φ1.8 | CERAMIC | |

| AA20C01 | Ø2.5 | Φ2.5 | CERAMIC | |

| AA0WT00 | Φ2.5G | Φ2.5 | RUBBER | |

| AA20D00 | Φ3.7 | Φ3.7 | CERAMIC | |

| AA18C00 | Φ3.7G | Φ3.7 | RUBBER | |

| AA20E00 | Φ5.0 | Φ5.0 | CERAMIC | |

| AA06300 | Φ5.0G | Φ5.0 | RUBBER | |

| SPECIAL | CNT | DATA for ON (LED, LENS) | SPECIAL |

- Maximizing Efficiency with FUJI NXT H24/DX Nozzles for Small Component Placement

The FUJI NXT H24 head nozzles, including models like 2AGKNX001407, 2AGKNX007500, 2AGKNX003905, 2AGKNX003705, and 2AGKNX001705, are designed for precise and efficient component placement in SMT applications. These nozzles handle a wide range of components with high suction strength, ensuring durability and minimal wear. Advanced designs such as 2AGKNX006300, 2AGKNX003100, 2AGKNX005503, and 2AGKNX005403 utilize high-quality materials like ceramic and rubber to improve placement accuracy, speed, and overall productivity. Additionally, variants like 2AGKNX005200, 2AGKNX003500, and 2AGKNX007600 are ideal for high-efficiency manufacturing environments where reliability and long service life are critical.

2.5G Nozzle 2AGKNX001407

2.5 Nozzle 2AGKNX003905

1.8 Nozzle 2AGKNX003705

1.3 Nozzle 2AGKNX001705

0.8 Nozzle 2AGKNX006300

0.7 Nozzle 2AGKNX003100

0.5 Nozzle 2AGKNX005503

0.4 Nozzle 2AGKNX005403

0.3 Nozzle 2AGKNX005200

1.0 Nozzle 2AGKNX003500

M Nozzle 2AGKNX007600

S Nozzle 2AGKNX007500

Item Table

| Item No. | P/N | Specification | ID |

|---|---|---|---|

| 1 | 2AGKNX0051 | R047-002-037 | H28 |

| 2 | 2AGKNX0052 | R047-003-037 | H29 |

| 3 | 2AGKNX0053 | R047-0035-037 | H30 |

| 4 | 2AGKNX0054 | R047-004-037 | H31 |

| 5 | 2AGKNX0055 | R047-005-037 | H32 |

| 6 | 2AGKNX0031 | R047-007-035 | H15 |

| 7 | 2AGKNX0063 | R047-008-035 | H33 |

| 8 | 2AGKNX0035 | R047-010-035 | H16 |

| 9 | 2AGKNX0017 | R047-013-035 | H17 |

| 10 | 2AGKNX0037 | R047-018-035 | H18 |

| 11 | 2AGKNX0039 | R047-025-035 | H19 |

| 12 | 2AGKNX0075 | R047-006WRS-037 | H35 |

| 13 | 2AGKNX0076 | R047-011WRM-035 | H36 |

| 14 | 2AGKNX0077 | R047-011WRL-035 | H37 |

| 15 | 2AGKNX0040 | R047-013M-035 | H22 |

| 16 | 2AGKNX0041 | R047-018M-035 | H23 |

| 17 | 2AGKNX0042 | R047-025M-035 | H24 |

| 18 | 2AGKNX0014 | R047-025G-035 | H25 |

| 19 | 2AGKNX0004 | JIG | J34 |

| 20 | 2AGKNX0045 | JIG φ1.3 | J44 |

| 21 | AA1AT | R07-003-070 | S10 |

| 22 | 2AGKNG0049 | R07-0035-070 | S61 |

| 23 | AA056 | R07-004-070 | S11 |

| 24 | 2AGKNG0041 | R07-005-070 | S60 |

| 25 | 2AGKNG0149 | R07-005C-070 | S63 |

| 26 | 2AGKNG0208 | R07-005-070 | S60 |

| 27 | AA057 | R07-007-070 | S12 |

| 28 | 2AGKNG0097 | R07-008-070 | S62 |

| 29 | AA05814 | R07-010-070 | S13 |

| 30 | 2AGKNG019600 | R07-0105-070 | S64 |

Item Table

| Item No. | P/N | Specification | ID |

|---|---|---|---|

| 31 | AA20A | R07-013-070 | S14 |

| 32 | AA20B | R07-018-070 | S15 |

| 33 | AA20C | R07-025-070 | S16 |

| 34 | AA20D | R07-037-070 | S17 |

| 35 | AA20E | R07-050-070 | S18 |

| 36 | 2AGKNG0216 | R07-006WRS-070 | S65 |

| 37 | 2AGKNG0217 | R07-011WRM-070 | S66 |

| 38 | 2AGKNG0218 | R07-018WRL-070 | S67 |

| 39 | AA064 | R07-013M-070 | S34 |

| 40 | AA19G | R07-018M-070 | S35 |

| 41 | AA065 | R07-025M-070 | S36 |

| 42 | AA0WT | R07-025G-070 | S56 |

| 43 | AA06A | JIG | J01 |

| 44 | AA4ZL | JIG | J06 |

| 45 | AA7AG | JIG | J16 |

| 46 | AA8MN | R19-013M-155-M | K34 |

| 47 | AA8MR | R19-018M-155-M | K35 |

| 48 | AA8MS | R19-025M-155-M | K36 |

| 49 | AA8ME | R19-025G-155-M | K56 |

| 50 | AA8MF | R19-037G-155-M | K57 |

| 51 | AA8MG | R19-050G-155-M | K58 |

| 52 | AA8MH | R19-070G-155-M | K59 |

| 53 | AA8MK | R19-100G-155-M | K60 |

| 54 | AA8ML | R19-150G-155-M | K61 |

| 55 | AA8MM | R19-200G-155-M | K62 |

| 56 | AA8KK | JIG | J23 |

| 57 | AA9CE | JIG | J27 |

| 58 | AA9CF | JIG | J28 |

| 59 | AA22Y | R19-013M-215 | T84 |

| 60 | AA22Z | R19-018M-215 | T85 |

| 61 | AA2KE | R19-025M-215 |

- Optimizing Production with FUJI NXTDX-R4 Placement Head Nozzles

The FUJI NXT DX-R4 head nozzles, including models 2AGKNM000303, 2AGKNM000205, 2AGKNM000805, 2AGKNM001304, 2AGKNM001205, 2AGKNM000609, 2AGKNM000508, 2AGKNM000406, and 2AGKNM000908, are specifically designed for high-precision SMT assembly lines. These nozzles accommodate a broad spectrum of component sizes and shapes, offering excellent compatibility and flexibility. Manufactured with high-quality materials such as ceramic, they deliver superior suction strength and resistance to wear, making them ideal for continuous, high-speed production environments. Their precision engineering ensures accurate placement, contributing to improved yield rates and overall manufacturing efficiency.

1.3 Nozzle 2AGKNM000303

1.0 Nozzle 2AGKNM000205

7.0 Nozzle 2AGKNM000805

5.0 Nozzle 2AGKNM001304

3.7G Nozzle 2AGKNM001205

3.7 Nozzle 2AGKNM000609

2.5 Nozzle 2AGKNM000508

1.8 Nozzle 2AGKNM000406

10.0 Nozzle 2AGKNM000908

Panasonic nozzles for CM & NPM

PANASONIC nozzles are known for their precision, reliability, and versatility in surface mount technology (SMT) applications. Designed to handle a wide range of component sizes, they ensure accurate placement and consistent performance. Made from high-quality materials such as ceramic and rubber, these nozzles provide strong suction power and durability, reducing wear and enhancing production efficiency. PANASONIC nozzles are engineered to deliver optimal speed and accuracy, making them ideal for both small and large-scale manufacturing. Their robust design minimizes downtime and improves overall SMT process efficiency, making them a trusted choice for many manufacturers in the electronics industry.

- Reliable Component Handling with PANASONIC CM402/CM602 Nozzles

PANASONIC CM402/CM602 nozzles are designed for high-precision placement in SMT applications, ensuring efficient and reliable component handling. Compatible with both CM402 and CM602 models, these nozzles offer versatility across a wide range of components. Made from durable materials like ceramic, they provide excellent suction power, minimizing wear and maximizing production efficiency. Their precision and durability make them ideal for high-speed manufacturing, contributing to improved accuracy and reduced downtime in SMT processes.

Nozzle 115AS N610017372AC

Nozzle 115 KXFX04MTA00

Nozzle 113N N610004642AA

Nozzle 110SN N610017371AC

Nozzle 110N N610099372AA

Nozzle 115AS N610017372AC

| PART No. | NAME | SPECIFICATION | MATERIAL | REMARK |

|---|---|---|---|---|

| 204CSN | 0.35×0.35 | CERAMIC | ||

| N610017370AC | 205CS | 0.65×0.35 | CERAMIC | 0603 |

| N610030510AC | 206CS | 0.5×0.6 | CERAMIC | 0603~1005 |

| N610038265AA | 256CSN(203ZSN) | 0.45×0.3 | CERAMIC | 0402 |

| 101YCO-K0210 | 210CS | 1.1×0.6 | CERAMIC | 1005 |

| 218CS(209CS) | 0.6×0.5 | CERAMIC | 1005 | |

| N610040786AA | 225CSN | 0.6×0.35 (X) | CERAMIC | 0603 |

| N610119480AB | 226CSN | 0.5×0.6 (X) | CERAMIC | 0603~1005 |

| N610119484AB | 230CSN | 1.0×0.7 (X) | CERAMIC | 1005~1608 |

| N610119485AB | 235CSN | 1.6×0.8 (王) | CERAMIC | 1608~3216 |

| N610119486AB | 240CSN | Φ2.4/Φ1.8 | CERAMIC | 3216~4512 |

| N610119444CB | 110CSN | Φ0.6/Φ0.45 | CERAMIC | 1005 |

| N610119444AB | 110SN | Φ0.6/Φ0.45 | METAL | 1005 |

| N610119450CB | 115CSN | Φ0.9/Φ0.65 | CERAMIC | 1608 |

| N610119450AB | 115SN | Φ0.9/Φ0.65 | METAL | 1608 |

| N610119456CA | 120CSN | Φ1.3/Φ0.9 | CERAMIC | 2125 |

| N610119456AA | 120SN | Φ1.3/Φ0.9 | METAL | 2125 |

| N610119461AA | 130SN | Φ2.4/Φ1.8 | METAL | 3216 |

| N610119473AA | 140SN | Φ4.0 | RUBBER | IC |

| N610126849AA | 161SN | Φ1.3/Φ0.9 | METAL | MELF |

| 162S | Φ1.8/Φ1.2 | METAL | MELF |

Nozzle 1006 KXFX037XA00

Nozzle 1005N N610098973AA

Nozzle 1002 KXFX037TA00

Nozzle 140S N610043702AA

Nozzle 130 KXFX0385A00

Nozzle 120 KXFX0384A00

| PART No. | NAME | SPECIFICATION | MATERIAL | REMARK |

|---|---|---|---|---|

| 204CN | 0.35×0.35 | CERAMIC | ||

| N610000995AA | 205A | 0.65×0.35 | CERAMIC | 0603 |

| N610015533AA | 206A | 0.5×0.6 | CERAMIC | 0603~1005 |

| N610029201AA | 256CN(203ZN) | 0.45×0.3 | CERAMIC | 0402 |

| 101YCO-K0210 | 210A | 1.1×0.6 | CERAMIC | 1005 |

| 218(209) | 0.6×0.5 | CERAMIC | 1005 | |

| N610040782AA | 225CN | 0.6×0.35 (X) | CERAMIC | 0603 |

| N610119490AB | 226CN | 0.5×0.6 (X) | CERAMIC | 0603~1005 |

| N610119493AB | 230CN | 1.0×0.7 (X) | CERAMIC | 1005~1608 |

| N610119496AB | 235CN | 1.6×0.8 (王) | CERAMIC | 1608~3216 |

| N610119499AB | 240CN | Φ2.4/Φ1.8 | CERAMIC | 3216~4512 |

| N610099372CA | 110C | Φ0.6/Φ0.45 | CERAMIC | 1005 |

| N610099372AA | 110N | Φ0.6/Φ0.45 | METAL | 1005 |

| N610099373CA | 115C | Φ0.9/Φ0.65 | CERAMIC | 1608 |

| N610099373AA | 115N | Φ0.9/Φ0.65 | METAL | 1608 |

| N610099374CA | 120C | Φ1.3/Φ0.9 | CERAMIC | 2125 |

| N610099374AA | 120N | Φ1.3/Φ0.9 | METAL | 2125 |

| N610099375AA | 130N | Φ2.4/Φ1.8 | METAL | 3216 |

| N610099376AA | 140N | Φ4.0 | RUBBER | IC |

| N610126847AA | 161N | Φ1.3/Φ0.9 | METAL | MELF |

| 162N | Φ1.8/Φ1.2 | METAL | MELF | |

| KXFX0387A00 | 450 | Φ6.0 | RUBBER | SOP, QFP |

| KXFX03NGA00 | 460 | Φ10.0 | RUBBER | Large Component |

- Enhancing Precision with PANASONIC AM100 Nozzles in SMT Production

AM100 machine nozzles are designed for high-precision pick-and-place operations in SMT (Surface Mount Technology). They are crafted to handle a wide range of component sizes, ensuring efficient placement with minimal defects. With a focus on durability and reliability, AM100 nozzles are compatible with various models, enhancing machine performance and operational efficiency. Their robust ceramic and metal materials ensure longevity and consistent high-speed performance, making them a critical component in automated assembly processes.

Nozzle 822MR MTKU001278AA

Nozzle 737M MTKU000402AA

Nozzle 750S MTKU006069AA

AM100 NOZZLE 240MT

Nozzle 185M N610156285AD

Nozzle 310M MTKU005430AA

| NAME | Specification | Material | Remark |

|---|---|---|---|

| 256M | 0.45×0.3 | CERAMIC | 0402 |

| 225M | 0.6×0.35(X) | CERAMIC | 0603 |

| 226M | 0.5×0.6(X) | CERAMIC | 0603, 1005 |

| 230M | 1.0×0.7(X) | CERAMIC | 1005, 1608 |

| 235M | 1.6×0.8(王) | CERAMIC | 1608~3216 |

| 387M | 1.6×1.1 | CERAMIC | 3216, 4532 |

| 120MT | Ø1.3/Ø0.9 | METAL | 2012, 3216 |

| 240MT | Ø2.4/Ø1.8 | METAL | 3216, 4532 |

| 260M | Ø5.0/Ø3.0 | METAL | TAN |

| 184MTR | Ø6.0/Ø4.0 | METAL | SOP, QFP |

| 140M | Ø4.0 | RUBBER | IC |

| 185M | Ø6.0 | RUBBER | QFP, PLCC |

| 388M | Ø7.0 | RUBBER | QFP, PLCC |

| 389M | Ø8.0 | RUBBER | QFP, PLCC |

| 199MR | Ø10.0 | RUBBER | Large Component |

Choosing the Right Siemens Siplace Nozzles for Your SMT Production

Siemens Siplace machines—like the X, S, SX, and D series—are known for high speed, precision, and flexibility. The SX and X suit high-mix production, while the S and D series are ideal for reliable, cost-effective SMT assembly.

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

Siemens nozzles are key to accurate, efficient SMT production. They ensure stable pick-and-place for various components and boost reliability in Siplace machines.

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

How to Choose the Right Juki Nozzle

Choosing the right Juki nozzle is key to efficient SMT production. Match nozzle size with component size to ensure accurate placement. Consider your production needs—high-speed lines may need durable, fast-switching nozzles. Also, compare materials: ceramic offers precision and wear resistance, rubber is ideal for delicate parts, and stainless steel provides durability for heavy-use environments.

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

| PART No. | NAME | Specification | Material | Remark |

|---|---|---|---|---|

| E3608-729-0A0 | 500 | 1.0×0.5/2-HOLE | METAL | 1005 |

| E3600-729-0A0 | 501 | Φ0.7/Φ0.2 | METAL | 0603 |

| E3601-729-0A0 | 502 | Φ0.7/Φ0.35 | METAL | 1005 |

| E3602-729-0A0 | 503 | Φ1.0/Φ0.6 | METAL | 1608 |

| E3603-729-0A0 | 504 | Φ1.5/Φ1.0 | METAL | 2125 |

| E3604-729-0A0 | 505 | Φ3.5/Φ1.7 | PAD | |

| E3605-729-0A0 | 506 | Φ5.0/Φ3.2 | PAD | |

| E3606-729-0A0 | 507 | Φ8.5/Φ5.0 | PAD | |

| E3607-729-0A0 | 508 | Φ9.5/Φ8.0 | PAD |

ERSA Wave Soldering Nozzle Applications and Benefits

Ersa wave soldering nozzles offer excellent soldering consistency and reliability, ensuring stable performance across production runs. Their precise design helps reduce common defects like solder bridging and cold joints. These nozzles are also ideal for complex double-sided PCBs and high-density component layouts, making them a reliable choice for advanced SMT and through-hole assembly applications.

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

Optimizing Fluid Dispensing with Camalot and Juki Needles

Dispenser needles are crucial in applying solder paste, adhesives, and other fluids to PCBs. Camalot and Juki offer high-quality needles known for precision and reliability. Camalot needles excel in durability and handling various viscosities, while Juki needles are recognized for their precise and consistent performance in automated systems. Both ensure efficient, high-quality dispensing.

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

Enhancing Efficiency with Customized Nozzles from Leading Brands: Fuji, Panasonic, Juki

Customized nozzles are essential for optimizing the pick-and-place process in SMT assembly, allowing precise handling of different component types and sizes. Brands like Fuji, Panasonic, and Juki offer a variety of customized nozzles designed to meet specific production needs. Fuji nozzles are known for their versatility and compatibility with various component types, while Panasonic nozzles provide high precision and durability for long-lasting performance. Juki nozzles are tailored to enhance pick-and-place efficiency, ensuring accuracy and reducing defects in assembly. Customized nozzles from these brands help improve overall productivity and quality in the manufacturing process.

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

In conclusion, SMT nozzles are crucial components that significantly impact the efficiency and precision of the pick-and-place process in SMT assembly. The right nozzles, whether customized or standard, ensure accurate placement of components, reduce defects, and enhance overall productivity. Leading brands like Fuji, Panasonic, and Juki provide a wide range of nozzles designed to meet various production requirements, from high precision to durability. By selecting the appropriate nozzle for your specific needs, you can improve the consistency, speed, and quality of your PCB assembly process, ultimately contributing to cost savings and higher-quality products. Proper nozzle maintenance and selection are key to achieving optimal results in any SMT operation.